Services

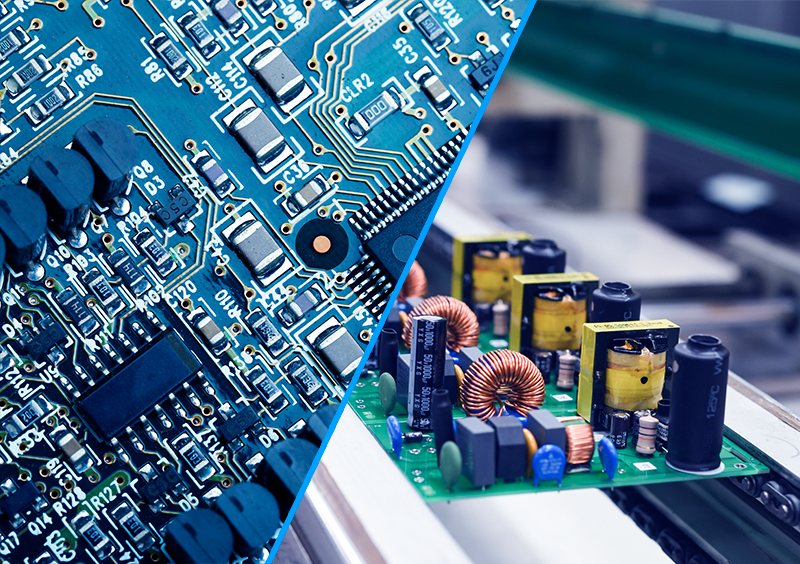

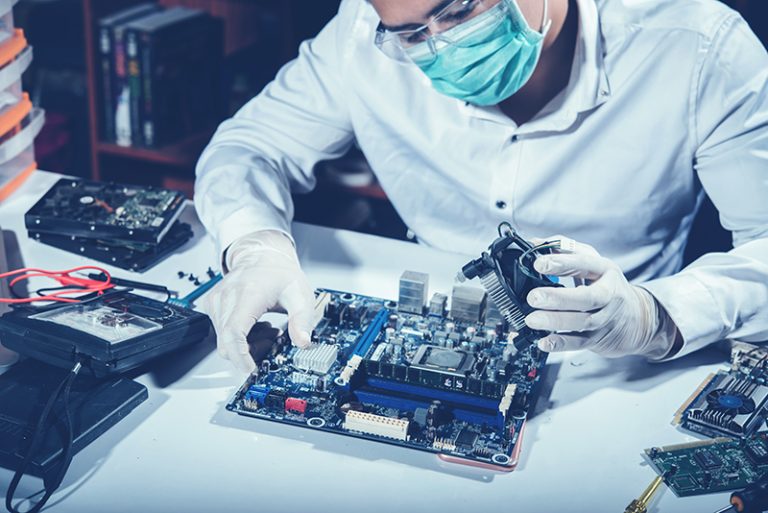

PCB Assembly:

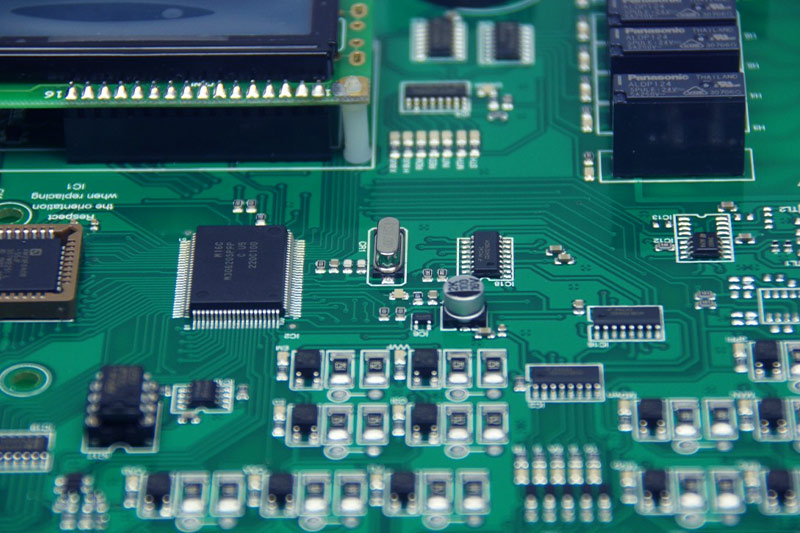

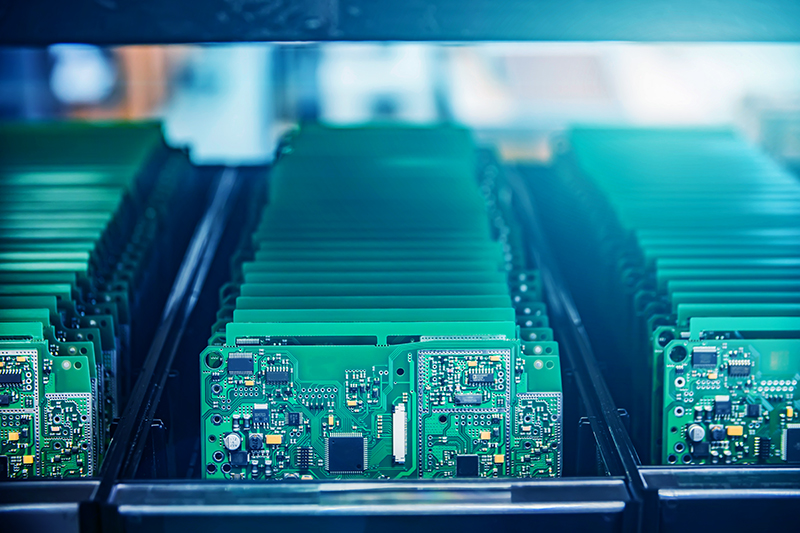

SMT Production Lines:

Our SMT production lines embody top-tier technology and performance.

- Automatic SMT Production Lines: 4 automatic production lines equipped with SMT technology for precision and efficiency.

- Maximum PCB Size: 400mm x 400mm, enabling the production of large-sized electronic boards.

- Component Types: Chip, MELF, SOT, SOIC, TSOP, PLCC, QFP, BGA, LCC, covering a wide range of requirements.

- Footprint Size: 01005, micro BGA, fine pitch packages

THT Production Lines :

Our THT production lines enable the production of high-quality boards with THT technology.

- Automatic PCB Assembly: Automatic assembly of PCBs with precision and reliability.

- Wave Soldering: Wave solder technology ensures uniform and reliable soldering of THT components.

- Pogo Pins Soldering: Specialized process for soldering Pogo Pins for exceptional stability and performance.

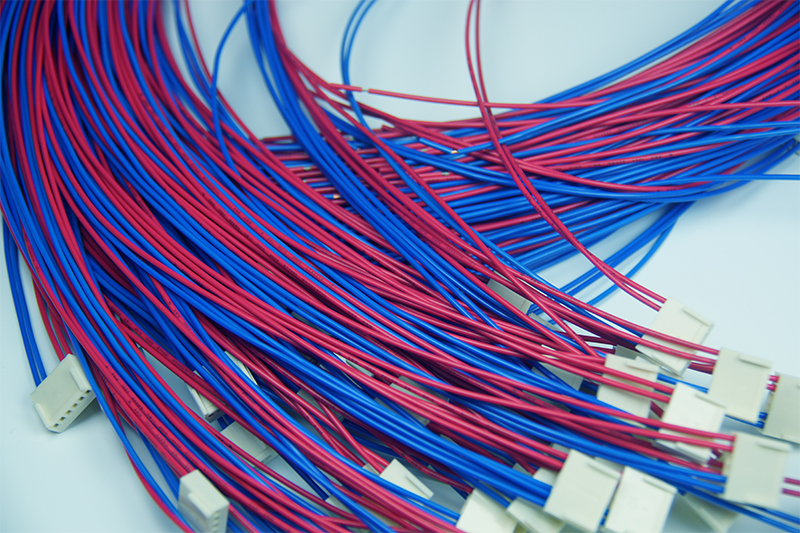

Production Lines Cables:

- Wire Measurement, Cutting, and Shaping: We employ advanced equipment for precise measurement, cutting, and shaping of wires according to specifications.

- Wire Stripping and Insulation Removal: We achieve precise wire stripping and insulation removal for safe and reliable use.

- RoHS Compliant Soldering: We use materials compliant with RoHS standards for environmental protection and safety.

- Assembly of Various Connector Types: Our team specializes in assembling various connector types, ensuring secure connections.

- Printing on Wires or Connectors: We provide printing services on wires or connectors for customized solutions.

- Automatic Optical/Functional Inspection: Our line is equipped with automatic optical and functional inspection.

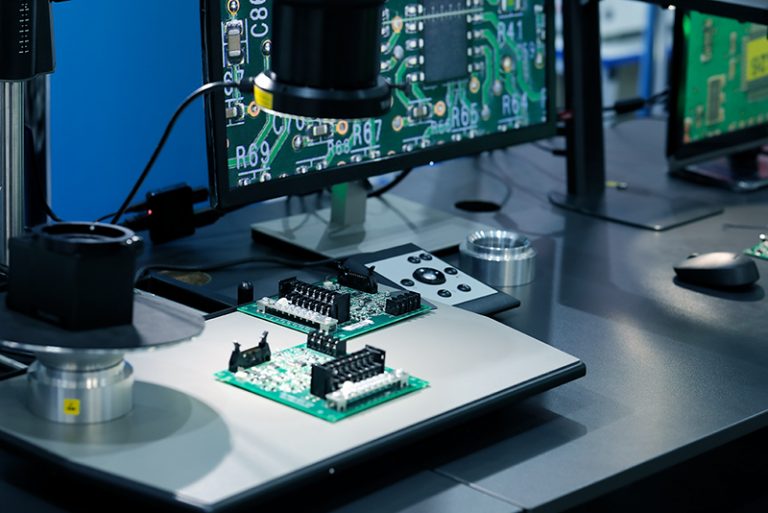

Quality Control Lines:

At NISSOU S.A., we invest in advanced quality control lines to ensure the quality and safety of our products.

- Optical Inspection with Microscopes: We use microscopes for precise and detailed optical inspection of our products.

- Automatic AI Optical Inspection for SMT & THT Materials: We implement advanced Artificial Intelligence (AI) techniques for automatic optical inspection of Surface Mount Technology (SMT) and Through-Hole Technology (THT) materials, utilizing both 2D AOI and 3D AOI technology.

- Functional Testing of PCBs & Finished Products: We perform functional testing on both PCBs and our finished products to ensure their safety and performance.

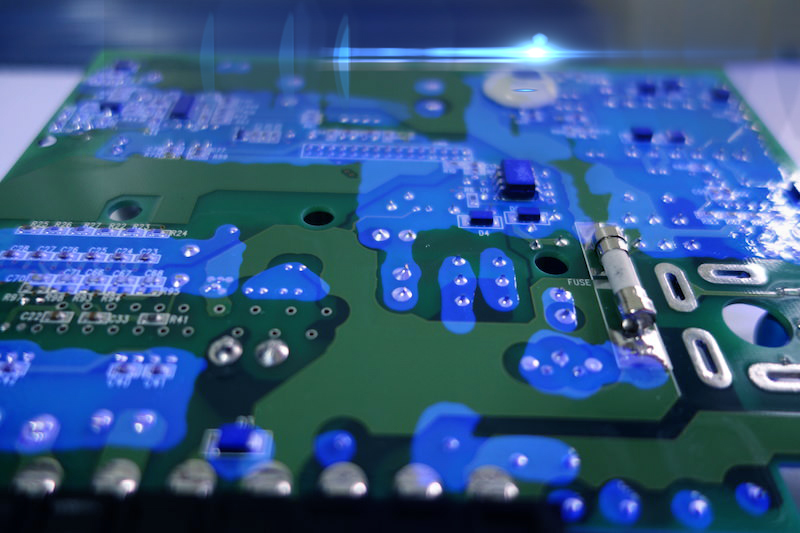

Additional Processes:

Additional Processes: We offer additional services that enhance the quality and functionality of our products.

- Product and PCB Coating:

- Sealing Materials

- Placement of Peelable Mask on PCB

- Potting

- Automatic Washing Machines:Extensive cleaning of PCBs in specialized washers using high-quality materials and state-of-the-art washing programs.

- Depaneling: Precise cutting and separation of individual boards from larger panels. SMT Rework with Automatic Machine:

- SMT rework: Utilization of automated machines for Surface Mount Technology (SMT) rework, ensuring effective and precise corrections.

Industrial solutions:

At NISSOU S.A., we offer specialized industrial solutions that cover a wide range of needs.

- Box Build Assembly: We combine multiple processes to create integrated products.

- PCB and Wiring Connection: We ensure safe and effective connection of PCBs and wiring.

- Programming: We provide programming services to ensure the efficient operation of products.

- Functional Testing: We perform functional testing to improve performance and reliability.

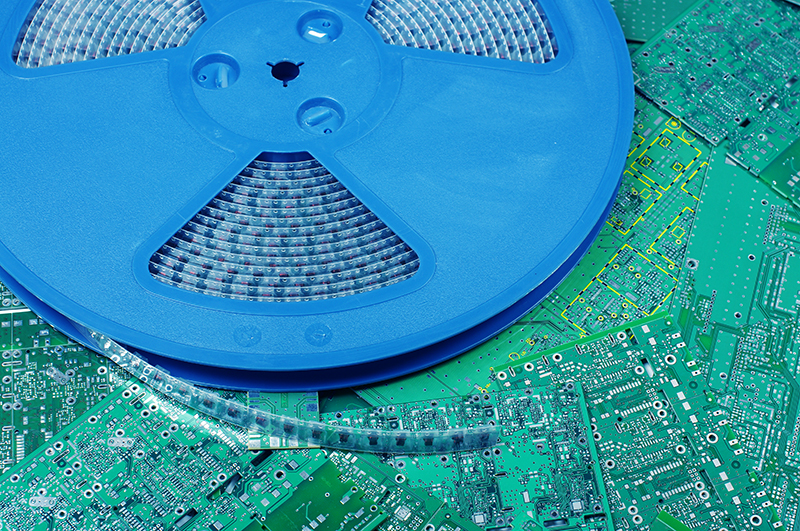

Procurement Solutions:

We emphasize efficient management of materials to ensure the quality and effectiveness of our processes.

- Supply of A’ materials: Sourcing high-quality raw materials to meet the needs of our production.

- Raw Material Inspection: Strict inspection procedures to guarantee the quality and specifications of raw materials.

- Traceability Marking: Implementation of marking for comprehensive traceability.

- Specialized Material Storage (Dry Environment Storage): Storage of materials in specially designed areas with controlled environments, ensuring optimal conditions.

- Pre-Bake: Pre-baking processes to prepare materials for construction.

- Inventory Management: Effective inventory management to optimize production processes.

Traceability of PCBs via QR Code:

We have adopted the innovative technology of PCB traceability through QR codes to enhance our production processes and ensure high quality in our products.

- Improvement of Production Processes: Users can easily track the progress of PCBs through the QR code, enhancing transparency and efficiency in production.

- Defect Detection and Removal: The system immediately detects defects during production, allowing for quick reaction and correction.

- Quality Improvement: QR code traceability contributes to the improvement of production quality and continuously ensures high standards.

Logistics:

We offer advanced logistics solutions to meet our customers’ needs with efficiency and environmental care.

- Customized Packaging Solutions: We provide personalized packaging solutions tailored to each customer’s needs.

- Ecological Packaging Solutions (ECO FRIENDLY): We adopt eco-friendly packaging solutions to reduce environmental footprint.

- Hybrid Shipping: We offer hybrid shipping solutions that ensure safe and efficient transportation of products.